The Steel

Detailer Help

The Steel

Detailer Help The Steel

Detailer Help

The Steel

Detailer Help

·

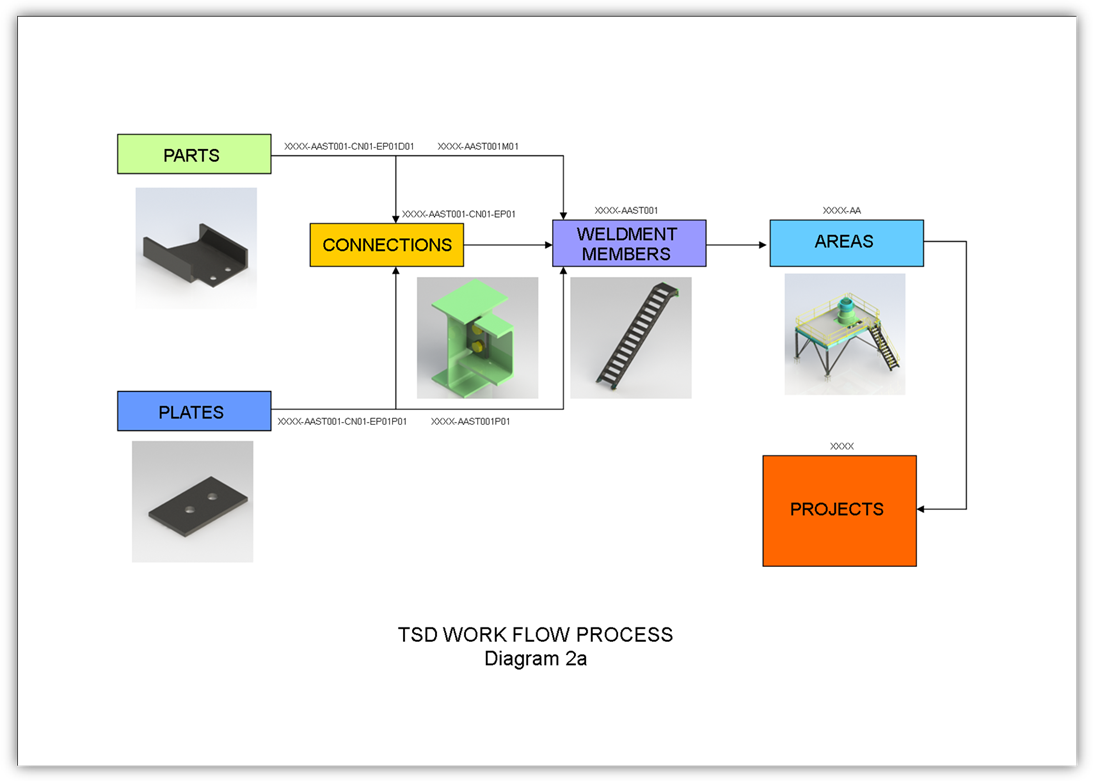

Below is a Typical breakdown for the various levels

with a TSD project, these levels will depend on the project requirements to

determine what is required and when,

When considering the Workflow of Steel

detailed projects there are many processes at play depending on the order of

events.

In fact it’s

incredible how much work is carried out

Usually

its

i) Builder\Architect\

Fabricator supplies quotation data

ii) Architectural

and Structural Engineering Drawings Received

iii) Quote

Produced and 1/10 of jobs won

iv) There

are a couple of reason you won the Job

(1) Cheaper

than everyone else

(2) Repeat

Business – client knows your work

(3) Availability

and timing

v) Project

Layout Commences

vi) TQ\RFI’s

travel backwards and forwards between Architect, Structural Engineer and

Fabricator and yourself.

vii) Layout

is Completed

viii) Layout

is Checked

ix) Cut List\Plate

List\Bolt Schedule is supplied for ordering

x) Drawings

are completed whilst the layout is being checked.

xi) Deliverables

are submitted for approval

(1) General

Arrangement Drawings

(2) Detail

Drawings

(3) Plate

Drawings

(4) Purlin

Drawings

xii) Structural

Engineer Check

xiii) Structural

Modifications

xiv) Deliverables

are Issued for Construction

(1) General

Arrangement Drawings

(2) Detail

Drawings

(3) Plate

Drawings and 1:1 dxf’s

(4) Purlin

Drawings

xv) Project

Completed

So

how is it managed ? Steps i)

through to iv) is document management.

v) Project Layout Commencement is where The

Steel Detailer starts.

Imagine that everything starts with a Driving

Sketch, Parts and Sub-Assemblies in SolidWorks. The Steel Detailer is exactly the

same. The only difference is that you are not fishing through previous projects

to find models used before. The Steel Detailer allows you to store them in a

common library\Archive location based on filtering for fast searching.

The Above diagram outlines this.